Our process

We believe that delivering quality is our responsibility and we never stop getting better at it.

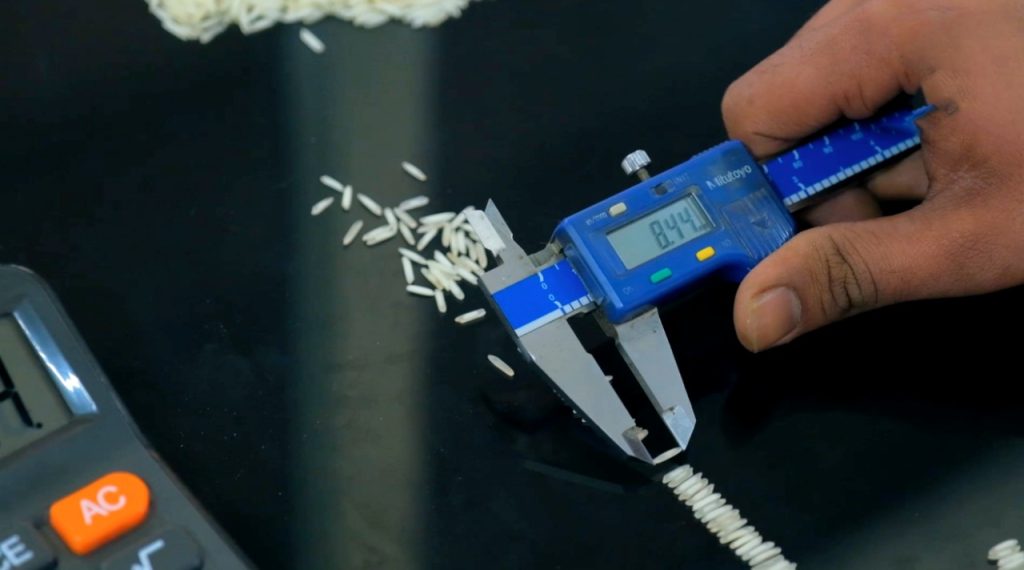

During the manufacturing process we use specialized equipment’s and tools to ensure the highest quality of rice.

The entire process is well documented to the minutest detail below to give you a fair idea of where our rice really comes from.

state-of-art production facilites

modern and scientific sourcing

poilicy

automatic packaging facilities

various stage quality checks

the entire process is well documented

We Believe quality means doing it right even when no one islooking.

Strong technical force, scientific management mechanism, advanced production equipment,s, superior lab quality checks and excellent after sales service.

step 1

Natural Himalayan water processing - We believe in purity

RRM cultivates the rice in the Himalayan foothills of India. The water of the Himalayas is known as mineral-rich which adds purity & better quality nutrition to the crops. The rice is cultivated in the fertile soil of Tohana, Haryana using both traditional & modern scientific methods to serve the best quality rice on your meal table. We believe that only nature can preserve the essence that our product holds and should thereby be processed in the most organic way possible. The crop (paddy) is then shifted to the mill for milling, where it goes in the storage bin (also known as hoddi).

Paddy Cleaning & Destoning

step 2

step 3

The Parboiling Unit

- Boling Rice fills up the grain cracks that would have otherwise taken a year to get filled

- Boiling Rice cuts down on the breakage of the rice

- Boiling Rice Improves the overall quality of the rice

After the process, there’s a unique drying plant that ensures the quality and uniform drying of paddy grains without breaking them. The paddy goes to the dryers which dry the paddy through hot air and then the paddy is ready for milling.

The Husk Cleaning Process (Dehusking)

As the paddy grains migrate between two abrasive surfaces moving at different speeds, friction removes the husk from the rice. The paddy goes to the boiler again wherein it burns the husk further.

step 4

step 5

The Paddy Separator

Rice Polishing

step 6

step 7

Rice Smoothning With Water Jet Polisher

Rice Color Sorting

step 8

step 9

Rice Length Grader

Packing Units

step 10